As we continuously seek sustainable energy solutions, solar energy remains the focus of discussion. Enter the world of organic solar cells, a fascinating innovation in the field of photovoltaic technology – often referred to as the third-generation solar cell. Different from traditional silicon-based solar panels, organic solar cells use organic materials to convert sunlight into electricity. What are organic solar cells? Organic solar cells (OSC) are a photovoltaic (solar) technology that uses organic materials (carbon-based compounds) to convert sunlight into electricity.

Unlike traditional solar cells that rely on inorganic semiconductors such as silicon, organic solar cells use organic polymers or small molecules as the active substances in the cells. The main advantage of organic solar cells lies in their versatility; they can be produced using various processes, including printing, which opens up exciting possibilities for manufacturing and application.How do organic solar cells work? The working principle of organic solar cells is the same as that of traditional solar cells: sunlight is absorbed by the active substances in the cells, generating excited electrons and holes, thereby generating an electric current. Here is the detailed working principle of this process: Light absorption: When sunlight shines on organic materials, it excites electrons, and the electrons will transition to a higher energy state.

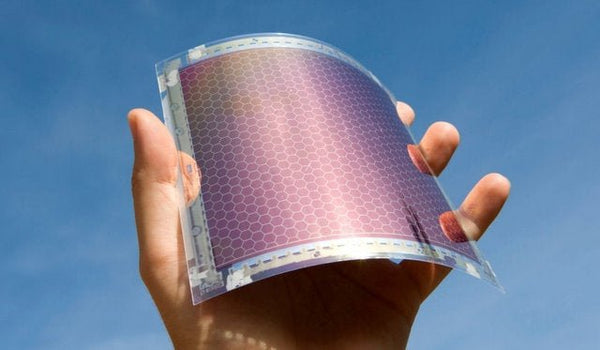

Charge separation: This excited state will generate electron-hole pairs (also known as excitons). The bonds between these pairs in organic materials are often weak, so they are easier to separate into freely moving charges. Charge transfer: These charges (electrons and holes) pass through the material and are collected by electrodes, and then guide the flow of current. Types of organic solar cells There are various types of organic solar cells, but the two most common types are: Organic photovoltaic cells (OPV): This is the more common type and uses polymer-based materials as the light-absorbing component. Organic dye-sensitized solar cells (DSSC): These cells use organic dye molecules to absorb light and then excite electrons in semiconductor materials to generate an electric current. Structure of organic solar cells The structure of organic solar cells (OSC) is different from that of traditional silicon-based solar cells. Organic solar cells consist of six layers, and each layer has a specific function to facilitate the conversion of sunlight into electricity. 1. Base layer The substrate is the base layer of the solar cell and provides mechanical support. It can be made of various materials, including glass, plastic, or metal, depending on the intended use. Flexible organic solar cells use flexible plastic substrates, which makes them lightweight and bendable. 2. Electrode layer The electrode is a conductive layer used to collect and transfer the charge carriers (electrons and holes) generated in the active layer.Organic solar cells consist of two electrodes: the anode (transparent electrode) and the cathode (metal electrode). The anode is made from transparent conductive materials such as indium tin oxide (ITO). This layer allows sunlight to pass through and reach the active layer while also collecting positive charge carriers (holes) generated by light absorption.

The cathode, made from metals like aluminum or calcium, collects negative charge carriers (electrons) and completes the circuit. The cathode is typically deposited on the organic layer using vacuum deposition methods. Between the electrodes and the active layer, a buffer layer or interlayer is often used to enhance the performance and stability of the solar cell. These layers serve multiple purposes, such as: – Hole transport layer (HTL): Located between the anode and the active layer, the HTL aids in transporting holes (positive charge carriers) to the anode. Materials like PEDOT:PSS (poly(3,4-ethylenedioxythiophene)-polystyrene sulfonate) are commonly used for this purpose. – Electron transport layer (ETL): Positioned between the cathode and the active layer, the ETL facilitates the transport of electrons to the cathode. Materials such as TiO₂ (titanium dioxide) are often used as electron transport layers. The active layer (photoactive layer) is the core of organic solar cells, where light is absorbed and converted into electrical energy. Made from organic materials, which can be polymers or small molecules, this layer generates excitons (electron-hole pairs) upon sunlight absorption. The structure of the active layer is crucial for the efficiency of the solar cell. Organic semiconductors in the active layer typically consist of electron donor and electron acceptor materials. These materials work together to create the photovoltaic effect, converting light energy into electrical current. – Donor materials: These are organic materials that release electrons when excited by sunlight. They are usually conjugated polymers. – Acceptor materials: Electron acceptor materials (often fullerenes or fullerene derivatives) receive electrons from donor materials, forming electron-hole pairs. – Bulk heterojunction (BHJ): Most organic solar cells utilize a bulk heterojunction structure, where donor and acceptor materials are mixed together to form a fine nanostructure. This improves charge separation and transport, enhancing the cell’s efficiency. After excitons are generated in the active layer, they need to be separated into free electrons and holes. Organic solar cells rely on the combination of donor and acceptor materials to create an internal electric field that drives the separation of charge carriers. The electron transport layer (ETL) and hole transport layer (HTL) help guide the separated charges to their respective electrodes for collection. Organic solar cells are sensitive to environmental conditions such as moisture and oxygen, which can degrade organic materials over time.To protect organic materials, encapsulation layers are necessary. These layers are typically made of polymers or glass, helping to protect the cells from external environmental impacts while allowing light to pass through. Overall structure diagram:

| Substrate (flexible or rigid) || —————————————————- || Transparent electrode (anode, ITO) || —————————————————- || Hole transport layer (HTL) || —————————————————- || Active layer (donor-acceptor blend) || —————————————————- || Electron transport layer (ETL) || —————————————————- || Metal electrode (cathode) || —————————————————- || Encapsulation layer (protective coating) | How does this compare to traditional silicon solar cells? Silicon solar cells are usually composed of solid silicon wafers sandwiched between protective material layers and electrode layers. They rely on p-n junctions formed by doping silicon with other elements to create the positive (p-type) layer and the negative (n-type) layer. The key differences lie in the materials and manufacturing processes. Organic solar cells are typically lighter and more flexible, and can be produced using simpler methods such as printing. In contrast, silicon cells are more rigid and require complex manufacturing processes. The simplicity of organic solar cells’ structure not only reduces production costs but also opens the door to innovative applications that are not possible with silicon cells. The lifespan of organic solar cells is generally shorter than that of silicon solar cells. However, while silicon solar panels have a lifespan of 25 to 30 years, organic solar cells typically last for 5 to 10 years with proper maintenance.Types of solar cells have varying average lifespans, with organic solar cells lasting 5 to 10 years and silicon solar cells lasting 25 to 30 years. This difference can be attributed to several factors: Material stability: Organic materials are more prone to degradation due to environmental factors such as moisture and UV radiation. Over time, these factors significantly impact their performance. Performance decline: While the performance of silicon cells gradually declines, the efficiency of organic cells may experience a more significant drop after just a few years. Technological improvements: Research is underway to extend the lifespan of organic solar cells. Innovations in material science aim to create more stable organic compounds resistant to environmental pressures. Compared to traditional silicon solar cells, organic solar cells generally have lower efficiency. While the efficiency of organic cells can reach 10% to 15%, silicon cells typically range from 15% to 22%, and even higher in advanced models. Factors contributing to this efficiency gap include: Light absorption: Organic materials have a different light absorption spectrum compared to silicon, limiting the amount of sunlight they can convert into electricity. Charge transport: The movement of charge carriers (electrons and holes) in organic materials is less efficient compared to silicon, affecting the overall energy conversion. In comparison to traditional silicon solar cells, organic solar cells generally have a lower initial cost, ranging from $0.50 to $1.00 per watt. In contrast, the cost of silicon solar cells is typically between $0.70 and $1.50 per watt. Factors contributing to this cost difference include: Manufacturing processes: Organic solar cells can be produced using simpler and potentially cheaper methods, such as printing, reducing labor and material costs. Material availability: The organic materials used in these cells are more readily available than the high-purity silicon required for traditional solar cells. Production scale: Although the cost of organic solar cells is currently lower, their production scale has not yet reached that of silicon cells. As production increases, prices may further decrease. Organic Solar Cell Materials: The materials used in organic solar cells (OSC) are fundamentally different from those used in traditional silicon solar panels. Here is a brief overview of the materials used in each: Organic compounds: Organic solar cells are primarily made from carbon-based materials, including small organic molecules and polymers.

These materials are responsible for light absorption and the conversion of sunlight into electrical energy.

Donor and Acceptor: The active layer of OSC typically consists of a mixture of electron donor and acceptor materials. Common examples include polymers such as poly(3-hexylthiophene) (P3HT) as donors and fullerene derivatives as acceptors. Substrate: The substrate can be flexible plastic or glass, enabling lightweight, bendable designs that traditional silicon cells cannot achieve. The applications of organic solar cells are vast. What are the advantages of organic solar cells? Firstly, they are lightweight and flexible, suitable for various surfaces. This means they can not only be integrated into roofs but also into windows, exterior walls, and even clothing. Imagine solar panels that can bend and conform to the shape of buildings, or integrated into your jacket to power your devices! In terms of future applications, organic solar cells may revolutionize several areas: Building-Integrated Photovoltaics (BIPV): Architects can design buildings with aesthetically pleasing and practical integrated solar solutions. Wearable Technology: Lightweight and flexible organic batteries can power wearable devices, enabling self-sufficient electronic devices without the need for bulky batteries. Mobile Devices: Imagine smartphones and tablets that can recharge themselves when exposed to light, reducing the need for frequent charging. Rural Electrification: In remote areas where traditional solar technology may not be practical, organic solar cells can offer a lightweight and cost-effective solution. Essentially, organic solar cells not only have the potential to improve the solar energy landscape but also make renewable energy more accessible and versatile in various applications. Are organic solar panels available now? Currently, despite the promising future of organic solar panel technology, they are not widely used in the market. Limitations of Organic Photovoltaics (OPV) technology, including durability, efficiency, and lifespan, mean they are still in the research and development phase. While there are prototypes and experimental devices, consumers cannot yet rely on them to meet energy needs. For those seeking reliable solar solutions, traditional silicon solar panels remain the best choice. They offer proven efficiency, longer lifespan, and robust performance under various environmental conditions. At At Hilden, we take pride in providing a series of high-efficiency solar panels designed to meet your energy needs while maximizing your return on investment. Our panels are designed with the latest technology to ensure durability and reliability, providing you with reliable energy for years to come.If you are considering using solar energy for your home or business, our traditional solar panels are an ideal choice before organic solar technology matures.